Instrument calibration is one of the main processes used to keep an instrument accurate. Many types of instruments can be calibrated and the process can be different for different types of instruments. However, it is always best to have an expert or calibrating service calibrate the instrument for you.

The main purpose of having an instrument calibrated is to ensure the instrument is accurate. If the instrument is not accurate, the measuring results in errors, giving you an untrue sample or unusable measurement. This is why it’s so important to have your instrument calibrated; you don’t want to end up with a poor or unusable reading.

Still unsure if you need your instrument calibrated or not? Find out here. Let’s review the process, types of instruments that should get calibrated, and how you can get your instrument calibrated.

1. What is calibration?

The word “calibrate” can be traced back to the American Civil War and has been thought to be a derivative from measuring the caliber of a gun. However, some of the earliest uses of the word come from ancient Egypt, where it was used for excavations to show angular gradations in construction. The term itself — calibration — means comparison.

Modern day instrument calibration involves configuring an instrument to provide a result for a sample within an acceptable range. It’s important to calibrate your instruments because when an instrument is calibrated, it has less chance of inaccurately measuring your sample. Therefore, calibration reduces measurement errors, giving you a clearer reading.

2. What type of instruments should be calibrated and when?

Some instruments that should be calibrated include but are not limited to thermo-hygrometers, T/RHP robes and measuring devices, data loggers, microbaths and dryblocks, and infrared thermometers.

An instrument may also need to be calibrated if it’s new, has been repaired or modified, the time period you’ve been using it has elapsed, before and after a critical measurement, and after an event. This is just a short list of when an instrument should be calibrated, you can find out more by checking with your preferred calibration service.

3. How is an instrument calibrated?

While each instrument is different and the exact calibration process may vary from product to product, the procedure is usually done by testing a sample of one or more values to test the accuracy of the instrument. During this process, the values are divided into samples, which are called “calibrators.” Testing the instrument helps to adjust any possible measurement errors that could occur and correct any problems.

The results of the value testing are then used to establish a relationship between the instrument and measurement technique. This process is called “teaches” and it helps the instrument produce more accurate results.

4. How can I get my instrument calibrated?

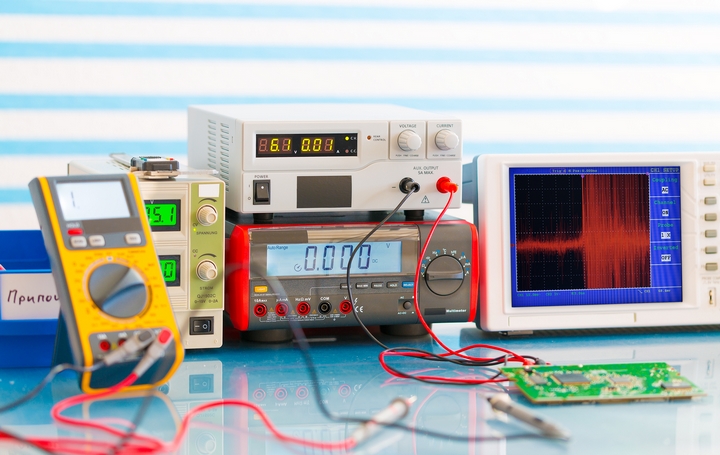

The two most popular ways to have your instrumented calibrated is on-site and offsite. On-site calibration services usually have a professional come to you. Offsite calibration means you send your instrument to a calibration company and they calibrate it at their office or warehouse.

Some of the benefits of having the service come to you include eliminating instrument downtime, minimizing interruptions for your manufacturing process, and no shipping costs or delays while waiting for your instrument to be returned.

If you have the time and don’t mind waiting, you can always send your instrument in to be calibrated. Sending your instrument allows the calibrating team to take their time and work on the instrument at their office. Offsite calibration services can be especially beneficial if the instrument needs special attention or requires other pieces.

5. Call your calibration professional

While this is just a basic overview of calibration and calibration services, you can always find out more by calling your local calibration professionals. If you’re unsure whether or not your instrument should be calibrated, it’s best to check before you start measuring — you wouldn’t want an inaccurate reading!